Water beading on top of sealed worktop

Sealing & Protecting Stone and Hard Surfaces

Hampshire Hard Floor Care Guide

A Complete Guide to Understanding Sealers, How They Work, and When You Need Them

Natural stone and high-quality tiles add beauty, character and long-term value to any home or commercial environment. However, most surfaces are naturally porous, meaning they can absorb liquids, oils and contaminants that gradually alter their appearance or lead to long-term damage.

The purpose of sealing isn’t to make a floor “maintenance-free” — it’s to control absorption, reduce staining, and make ongoing cleaning easier and safer.

This guide explains everything you need to know, from how sealers work to when you should (and shouldn’t) use them. And if you prefer expert help, we’re always here to advise or provide professional application.

1. Why Stone and Tile Need Protection

Most natural stones – such as limestone, travertine, marble, slate, sandstone and granite – contain microscopic capillaries. These tiny pathways allow moisture, oils and dirt to travel beneath the surface.

Without proper protection, you may see:

- Deep staining from food, drink, oil or general household/grime

- Dulling and darkening in walkways or busy zones

- Uneven patches where moisture enters at different rates

- Accelerated wear on softer stones

- Damage from incorrect cleaning products

A good sealer helps by:

- Creating a barrier inside the pores

- Slowing absorption

- Reducing the risk of permanent staining

- Making routine cleaning easier and more effective

Different stones need different levels of protection — some barely absorb water, while others absorb it instantly.

2. How We Assess Whether Your Stone Needs Sealing

Before recommending a product, we inspect and test the surface. This is essential because using the wrong sealer can cause hazing, patchiness or poor protection.

We assess four key factors:

A. Stone Type

Some stones absorb rapidly (limestone, sandstone, travertine), while others are dense (polished marble, granite).

Soft, open stones normally need

stronger, deeper-penetrating sealers.

B. Surface Finish

- Polished: Low absorption; sealing may be optional or light

- Honed/Brushed: Moderate absorption

- Textured/Riven: Very absorbent, high need for sealing

C. Environment & Usage

- Kitchens: oil + water risks → oleophobic sealers

- Bathrooms/wet rooms: cautious approach (risk of moisture trapping)

- Hallways: resistance to foot traffic + dirt

- Commercial settings: long-life protection and easy maintenance

D. Water Absorption Test

A simple on-site test gives a quick indication of porosity:

- Under 1 minute: very porous → strong protection required

- 1–4 minutes: porous → standard impregnator is suitable

- 4+ minutes: low porosity → targeted or minimal sealing

This helps us select the safest and most effective system.

3. Types of Protective Treatments

A. Surface Coatings (Film-Forming Sealers)

These create a physical layer on top of the stone, acting like a thin varnish.

They offer

surface-level protection but come with limitations.

Benefits

- Can add sheen or gloss

- Provide a “sacrificial” layer that takes wear

- Sometimes increase slip resistance

Limitations

- Prone to scuffing and scratching

- Build-up can look artificial or cloudy

- Can trap moisture

- Often need stripping and re-application

- Can yellow outside

We rarely use heavy coatings on premium stone floors because of these issues — but in certain scenarios (rustic slate, heavy commercial areas), a quality coating can be appropriate.

B. Impregnators (Penetrating Sealers)

This is the professional standard for most natural stone.

They penetrate into the pores and create an invisible barrier inside the stone.

No film is left on the surface.

Two main types:

Hydrophobic Impregnators

Repel water-based contaminants (tea, wine, coffee, etc.).

Oleophobic Impregnators

Repel BOTH water and oils — essential for kitchens, food-prep areas, bathrooms and high-traffic zones.

Advantages:

- Maintain natural appearance

- Long lifespan

- No peeling, flaking or yellowing

- Suitable for most interior and exterior surfaces

Important note:

Impregnators

do not prevent etching from acidic spills (lemon, vinegar, wine, cleaning products).

C. Nano Impregnators (Advanced Technology)

Nano-size particles penetrate deeper than conventional sealers, offering high-level protection:

- Exceptional resistance to oils, water and grime

- Long service life

- Excellent for porous stones and commercial sites

- Often PFAS-free alternatives available

These products strike the balance between natural appearance and high performance, making them ideal for premium floors.

4. Colour-Enhancing Sealers

Where deeper tones or richer colours are desired (slate, travertine, limestone, tumbled or textured finishes), colour enhancers can dramatically improve appearance.

They:

- Bring out natural veining

- Deepen warm hues

- Highlight variations

- Improve visual richness

They do not sit on the surface — they penetrate into the stone and leave a natural-looking enhanced finish.

We can apply a test patch so you know exactly what the stone will look like before committing.

5. Eco & Safety Considerations (PFAS, VOCs & Food Areas)

Many traditional sealers contain PFAS (“forever chemicals”) or high VOC levels. These can raise concerns for indoor air quality or kitchen surfaces.

We can specify:

- Low-VOC

- VOC-free

- PFAS-free

- Food-contact-safe

- Eco-friendly sealers

We’ll always choose the safest and most suitable product for your home.

6. Our Professional Sealing Process

The difference between DIY sealing and a professional finish is the quality of preparation and correct application. Our process includes:

1. Inspection & Testing

Identify stone type, absorption levels, any existing coatings, and the correct product.

2. Deep Cleaning

We thoroughly clean and rinse the surface to remove:

- Soil

- Residues

- Previous cleaners

- Grease

- Mineral deposits

A sealer cannot bond properly to a dirty or contaminated surface.

3. Drying

Stone must be dry before sealing — otherwise the sealer sits on moisture instead of bonding in the pores.

4. Application

We apply the correct amount, using the right method:

- Low-pressure sprayer

- Microfibre applicator

- Mop method

- Cloth application for worktops

5. Buffing / Removal of Excess

Any leftover product is removed before it cures — preventing sticky or hazy patches.

6. Curing

Cure times vary from 4 hours to 48 hours, depending on the product and location.

7. Aftercare Advice

We supply tailored guidance, including recommended cleaners and maintenance tips to prolong protection.

7. Densifiers for Soft Stone & Terrazzo

Some materials – like softer limestones and cement-based terrazzo – benefit from

densification.

Densifiers chemically react within the stone to:

Increase hardness

- Improve scratch resistance

- Tighten the pore structure

- Reduce dusting/powdering

- Extend the life of the floor

Often used in commercial or high-wear domestic environments, densifiers can be combined with impregnators for maximum performance.

8. Sealing in Wet Rooms & Outside — Proceed with Care

One of the biggest misconceptions is that wet areas always need sealing.

In constantly damp environments, impregnators can actually trap moisture, leading to:

- Dark marks

- Pitting

- Efflorescence

- Salt movement

- Spalling

For bathrooms, showers and outside areas, we choose vapour-permeable products — or recommend leaving the stone unsealed if sealing poses more risk than benefit.

9. Protecting Kitchen Worktops (High-Heat Considerations)

Kitchen surfaces experience more risk than floors:

- Hot oils

- Lemon/vinegar

- Spillages

- Abrasion around sinks

- Food preparation acids

Even the best impregnators can degrade when exposed to very hot oils or pans.

This is why we may recommend:

- More frequent top-ups around the hob

- Anti-etch coatings for marble

- Use of trivets and chopping boards

10. Anti-Etch Systems for Marble & Soft Stones

Standard sealers

cannot stop etching — the chemical reaction is instant.

For full protection, we offer

anti-etch systems: thin, invisible coatings or films that prevent both staining AND etching.

Perfect for:

- Marble kitchen islands

- Bar tops

- Bathroom vanities

- Commercial counters

These systems dramatically improve the practicality of acid-sensitive stones.

11. Frequently Asked Questions

Will sealing change how my stone looks?

Standard impregnators are invisible; enhancers deepen colour.

How long does sealing last?

From 1–10 years depending on stone type, traffic, and product.

Does sealing stop etching?

No — only anti-etch coatings stop etching.

Do exterior surfaces need sealing?

Not always; depends on stone type, drainage, and risk of moisture trapping.

Is sealing safe in kitchens?

Yes, once cured. Low-VOC and PFAS-free options are available.

12. Want Professional Help?

We offer fully trained, insured and experienced stone care services across Hampshire — from cleaning and restoration through to sealing, enhancement and anti-etch protection.

✔ Specialist products (including eco and PFAS-free options)

✔ Safe, long-lasting application

✔ Demo/test patches available

✔ Suitable for homes, heritage sites and commercial properties

If you’d like expert sealing or advice on your specific stone, we’d be happy to help.

Request a free quote or consultation any time.

Worktops restored on deck of P&O Britannia

Marble Vanity units aboard Cunard Queen Elizabeth, video shows No Etch in action, acid is poured onto surface, where there is no protection there is reaction and the acid fizzes which is what causes the etching, whilst there is no reaction on the treated part

Granite worktop sealed for protection

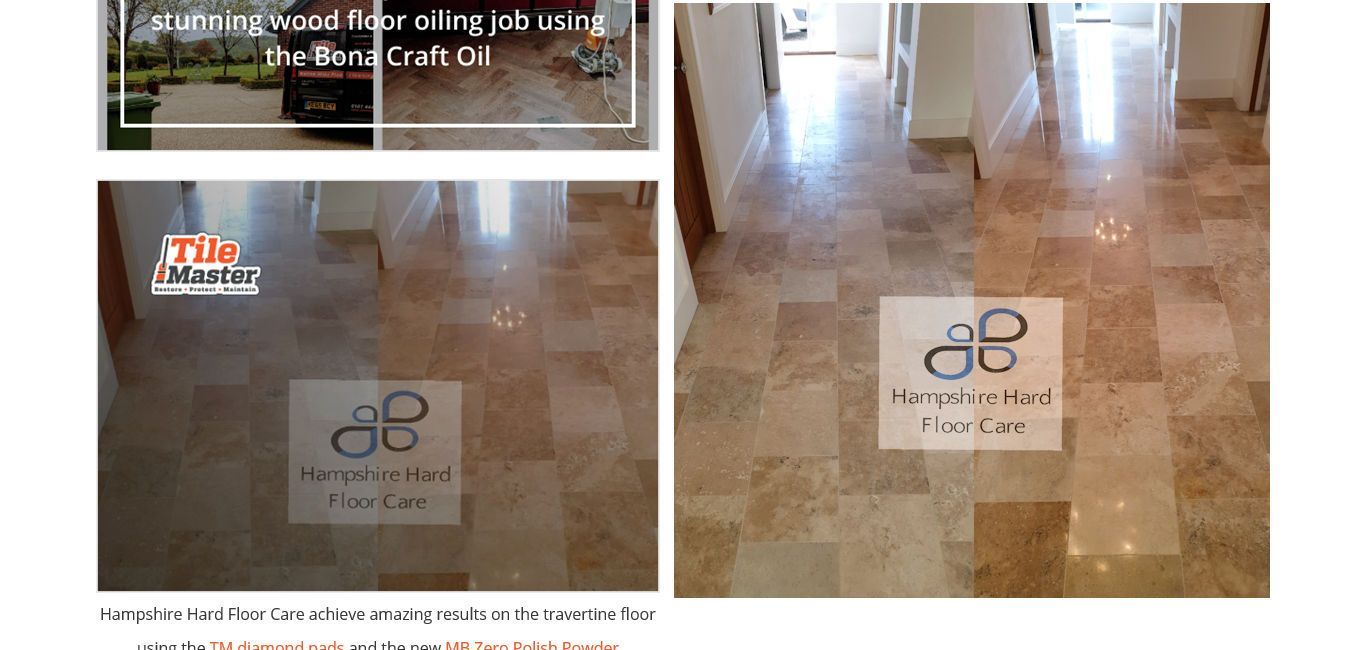

A travertine floor we polishe dwhich made it into a magazine using TileMaster solvent sealer